Specializing in high quality plating since 1955

Celebrating six decades of plating

Founded in 1955 by Mr. Dick Dixon himself, we’re committed to exceeding the strict plating requirements of the aerospace and aircraft overhaul industries, and we maintain the same high standards for every Dixon client.

With over six decades of experience, we’ve built Dixon Hard Chrome from the ground up by surpassing specifications and placing customer satisfaction at the core of our business.

We have over 10,000 square feet in the building complex and an additional 23,000 square feet of storage space. With our modern facilities, we’re able to process and deliver small and large orders quick and at a competitive cost.

We’ve successfully serviced millions of parts over the decades and built countless relationships with valued clients.

- F.A.A. Repair Station #TP3R875

- A TQM/SPC Qualified

- NADCAP Accredited

Plating Services

Hard Chrome

Copper Plating

Abrasive Finishing

Electroless Nickel

Plating On Aluminum

Cadmium Plating

Passivate

Chem Film

Nital Etch

Magnetic Inspection

Penetrant Inspection

Specifications

Military Specifications:

AMS-QQ-P-416, AMS 2400, BAC5701, DPS 9.28, HP 4-11, PS 13101, PS 13144

Classification:

Type 1 – Clear without supplementary chromate treatment

Type 2 – With supplementary chromate treatment, iridite (gold) and clear

Class 1 – .0005″ thick

Class 2 – .0003″ thick

Class 3 – .0002″ thick

Military Specifications:

MIL-STD-870, AMS 2401

Military Specifications:

AMS-QQ-C-320, AMS 2406, MIL-STD-1501, AMS 2438, AMS 2460, BAC 5709, DPS 9.71, DPS 9.84, HP 4-13, PS 13102

Classification:

Class 1 – Corrosion protective plating

Class 2 – Engineering plating

Boeing – Class 2, 3, 4

Military Specifications:

MIL-C-14550, AMS 2418 Type 1, BAC 5722, DPS 9.69, PS 13104

Classification:

Class 0 – .001″ – .005″ thick

Class 1 – .0010″ thick (for carburizing shield or brazing operations)

Class 2 – .0005″ thick (as undercoat for nickel and other metals)

Class 3 – .0002″ thick (to prevent basis metal migration into thin layer to poison solderability

Class 4 – .0001″ thick (same as .0002″)

Military Specifications:

MIL-C-5541, AMS-C-5541

Classification:

A corrosion resistant coating for aluminum and aluminum alloys.

Military Specifications:

MIL-C-26074, AMS 2404, DPS 9.67, PS 13105

Classification:

Class 1 – As coated condition

Class 2 – Conditioned (heated) for improved hardness

Class 3 – On aluminum

Class 4 – On aluminum

Military Specifications:

MIL-STD-753

Classification:

Method 100 Water Immersion Test

Method 102 COpper Sulfate Test

Military Specifications:

ASTM B117

Classification:

Salt Spray Test

Military Specifications:

AMS-2640, ASTM-E-1444, MIL-STD-1949, MIL-I-6868, BAC 5424, DPS 4.704, HP 6-5

Military Specifications:

MIL-STD-867, AMS 2649

Military Specifications:

MIL-S-5002, AMS 2700

Classification:

Surface treatments and inorganic coatings for metal surfaces of weapons systems

Military Specifications:

MIL-STD-171 (ORD)

Classification:

Finishing of metal and wood surfaces

Military Specifications:

MIL-STD-808 (USAF)

Classification:

Finishes protective, ground and ground support equipment

Military Specifications:

AMS-QQ-P-35

Classification:

Passivation treatment for corrosion resistant steels

Military Specifications:

AMS-2645, ASTM-E-1417, MIL-STD-6866, MIL-I-6866, BAC 5423, DPS 4.707, HP 6-13

Military Specifications:

MIL-STD-151

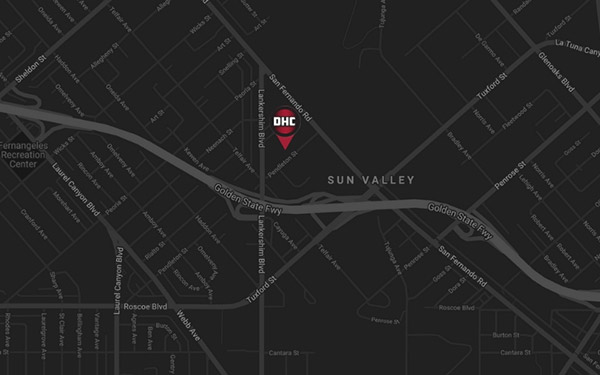

Contact or request a quote

Contact us by email or by phone

| DEPARTMENT | NAME | PHONE | |

|---|---|---|---|

| Shipping | Pablo Pena | shipping@dixonhardchrome.com | (818) 479-0571 |

| Quality Manager | Steve Arrington | sarrington@dixonhardchrome.com | (818) 479-0562 |

| Environmental Department | Jane Walner | jane@dixonhardchrome.com | (818) 479-0567 |

| Plant Manager | Javier Escobedo | javier@dixonhardchrome.com | (818) 479-0576 |

| Chrome Manager | Dyle Henderson | dyle@dixonhardchrome.com | (818) 479-0563 |

| Planning / Corrected Certs | Windsor Gaspard | windsor@dixonhardchrome.com | (818) 479-0561 |

| Order Status | Daniel Guevara | dan@dixonhardchrome.com | (818) 479-0564 |

| AP / Billing | Teresa Stamp | billing@dixonhardchrome.com | (818) 479-0566 |

| NDT Department | Ramon Alvarez | ndt@dixonhardchrome.com | (818) 479-0560 |

| Controller | Dioni Rodriguez | dioni.rodriguez@dixonhardchrome.com | (818) 479-0565 |

| Purchasing / Maintenance | Jesus Macias | jesus@dixonhardchrome.com | (818) 479-0567 |

| Quoting / Estimating | Francisco Capacho | francisco.capacho@dixonhardchrome.com | (818) 479-0568 |

| Price confirmation / Shipping Receiving | Elias Soria | elias@dixonhardchrome.com | (818) 479-0572 |

| Business Development Manager | Carmen Mejia | carmen.mejia@dixonhardchrome.com | (818) 482-4642 |